millions of hermit crab shells removed as souvenirs from the Maldives causing a species housing crisis

Author: Distil Ennui | Post Date: 23-03-2022NB - THIS POST HAS AN UPDATE - JANUARY 17th 2023 - LINKED HERE.

Hermit crabs are anomuran decapod crustaceans of the superfamily Paguroidea that have adapted to occupy empty scavenged mollusc shells to protect their fragile exoskeletons. There are over 800 species of hermit crab, most of which possess an asymmetric abdomen concealed by a snug-fitting shell.

Some time ago I began working on trying to find a solution to a problem that has been accelerating over the years with the continual bad behaviour of poorly educated tourists, by removing the shells from their natural habitat which sadly is almost impossible to control. So with this project I am hoping to offer a workable and ethical solution that would allow arriving guests to understand the pitfalls for the loss of this captivating little species from these islands. We are hoping to fabricate these in our VOC ventillated room at 'Makers Place' our carbon neutral plastic and aluminium recycling studio in the Maldives.

I have trialed two directions in the studio, both in glass and bio-resin. With glass there are several studios already fabricating this design around the world but ramping up to sizeable production numbers would prove a terminal a stumbling block; each piece is time consumingly intricate to make and energy intensive.

image courtesy www. glassshell .com

New Bio-Resins coming onto the market however do align with the environmental signature that I am looking for as they become fully inert once cured, and allow for scalable production using non petroleum or plastic based organic materials.

I have formulated a technical brief to bench test each bio-resin selected for the project and the suppliers involved have initially verified the efficacy, application process and durability of their products. They are selected for their uv stability, abrasion resistance (using Rockwell hardness tests) and once confirming that post curing that they are 100% leech free we can be satisfied. All of the selected bio-resins have differing percentages of plant based compound extracts the highest being 100% down to the lowest at 40%.

For the model itself, of course it should be nature that guides this design so while I replicated the species exactly in the first place, it was decided that this would be too heavy when formed in resin so an alternative had to be found.

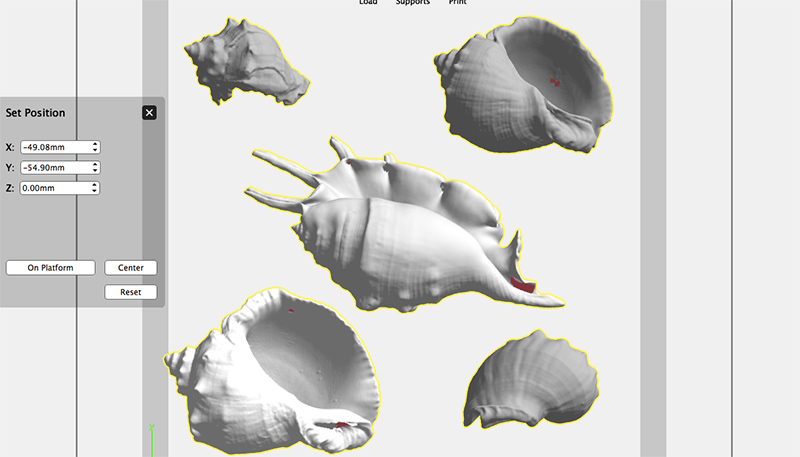

3d scans of complex hermit crab shells proved to heavy in design testing.

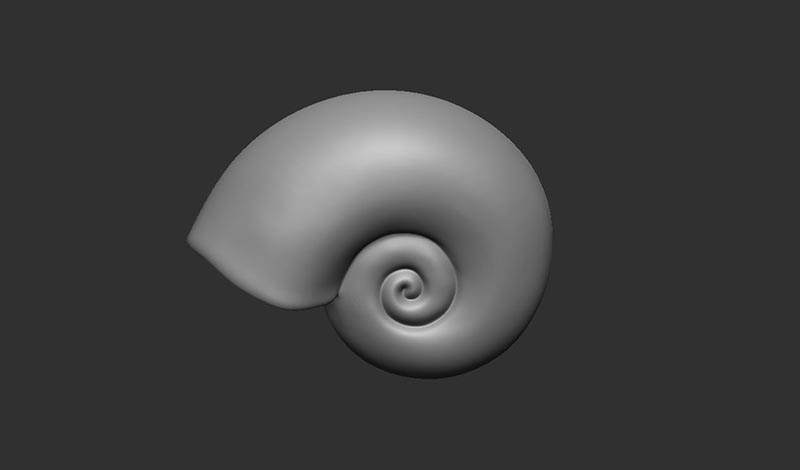

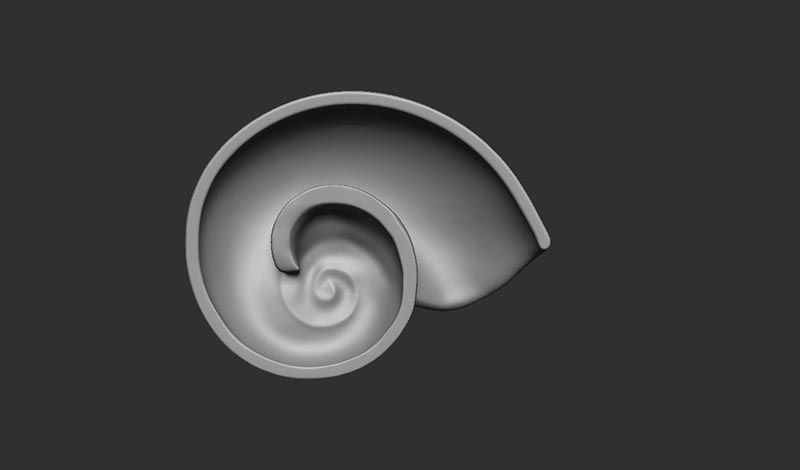

The cleanest design to be found of any shell is in fact the humble escargot or Helix Pomatia, so I scoured the local river banks and orchards during the wet season and collected naturally empty (dead) snail shells and using a 3d laser scanner in the studio I mapped their organic forms into a set of 3d mesh models.

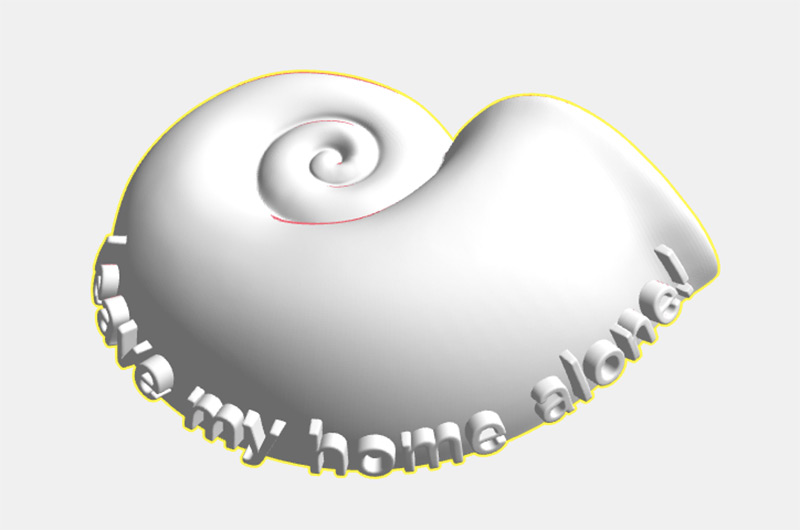

Right now the selected shell models are being modified to include some form of branded message to ward of potential tourists from removing them from the beach yet again. This design will then be taken to the 3d printing stage experimenting with scale to perfect them.

initial mock up of shell design with the text 'leave my home alone'

The aim within the studio is to create a set of multi-sized silicone rubber moulds so that we can make the final shells on the island in situ at ‘Makers Place’, Baa Atoll, Maldives. This would cut out the need for a supply chain and offer a verified ethical production process. This is an important cornerstone of all studio projects and a rare thing in todays world, I ask you to explore more about my thoughts on design and ‘going circular’ or ‘circularity’ here on an earlier journal entry.

Fabricating on location with a Bio-Resin makes sense as these products do emit a small amount of VOC vapour in the first curing stage lasting 30-90 minutes. If production is handled at ‘Makers Place’ we could capture all these vapours within the sealed plastics studio working with our VOC fume extraction/filtration system making the whole process completely harmless to the environment. With the added bonus from initial tests that I have made, the crabs themselves do seem to love occupying them.

The Distil Ennui Studio (the umbrella under which I work) has been engaged predominantly in community based environmental projects since 1990. My practice is driven by a lifelong interest in field observation, scientific discovery with a prominence in exploring the liquid mechanics of water. I believe it is my role to make the concerns of art relevant to society at large, a crucial means for turning thinking into doing in the world; spanning sculpture, painting, photography, film, lighting and installation. Not limited by the architectural confines of the art world, my practice engages the broader public sphere through interventions within natural landscapes and civic spaces alike, arts education, policy-making, issues of sustainability and ecocide.

I hope you found this journal entry informative, please stay connected.

Join the mailing list.. Register

Telegram Channel.. DistilEnnui

Instagram.. AJHamilton.Artist

Twitter.. DistilEnnui

Support on Patreon.. SustainableArt